A bored hole is a cylindrical hole created by drilling, boring, or reaming. It may be necessary to repair a bored hole if it becomes enlarged, damaged, or needs to be corrected. There are several ways to improve a bored hole, and the best method will depend on the problem that needs to be addressed.

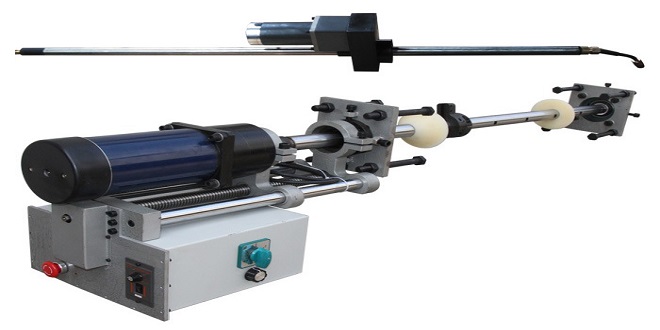

Counterboring

Counterboring is Bore Repair Perth technique that involves enlarging the hole bore to accommodate a more giant-diameter shaft. The enlarged bore is typically slightly tapered, with the largest diameter at the bottom of the bore. This allows the shaft to be seated more securely in the bore and helps to prevent the shaft from wobbling or working loose over time. By enlarging the bore, counterboring creates a more significant margin for error, making it easier to align the shaft with the bore. In some cases, counterboring may also be used to improve the alignment of misaligned holes. While counterboring is not always necessary, it can be an essential tool for ensuring long-term functionality and structural integrity. Also, when used in conjunction with other machining operations, counterboring can help to improve the overall finish of a part.

The cost of counterboring generally depends on the size and complexity of the enlarged bore. In most cases, counterboring is a relatively inexpensive machining operation. However, if the bore is very large or complex, the cost of counterboring can increase significantly. As with any machining operation, it is essential to consult a qualified machinist to determine the most efficient and cost-effective way to produce the desired results.

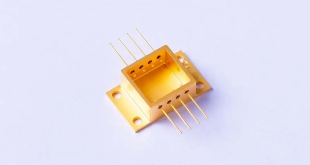

Laser Welding

Another way to repair a bored hole is through laser welding. Laser welding can be used to weld a new piece onto the existing bore, effectively creating a new, larger bore. This method is often used when the original bore needs to be enlarged to accommodate a new insert or cutting tool.

Laser welding is a process that uses a focused beam of high-energy light to weld two pieces of metal together. Compared to traditional welding methods, laser welding has several advantages:

- It is much more precise, allowing for Bore Repair Perth and other delicate procedures.

- It is faster and easier to set up, reducing downtime and increasing productivity.

- It produces less heat and debris, making it ideal for use in sensitive environments.

As a result, laser welding is an increasingly popular choice for manufacturers across various industries.

Despite its advantages, laser welding does have some limitations:

- It is more expensive than traditional welding methods.

- It requires special equipment and training, which can be barriers to entry for some manufacturers.

- Welding certain metals, such as aluminum and titanium, can be difficult.

Despite these challenges, laser welding is an increasingly popular choice for manufacturers across various industries.

There are several ways to repair a bored hole, and the best method will depend on the problem that needs to be addressed. In most cases, counterboring or laser welding will be the best option for repairing a bored hole.

Pagal World

Pagal World